Automatic Profiling and Oven Monitoring

Standard automation systems include two types of thermal monitoring systems:

Machine monitoring:

Continuous measurement of actual and historic changes in temperatures along the oven tunnel, conveyor speed, with ability to instantly alarm on excessive fluctuations.

Process monitoring:

Periodic automatic profiling of the PCB profile, and instant analysis of the relationship to the established process window. Alarm functionaries are available.

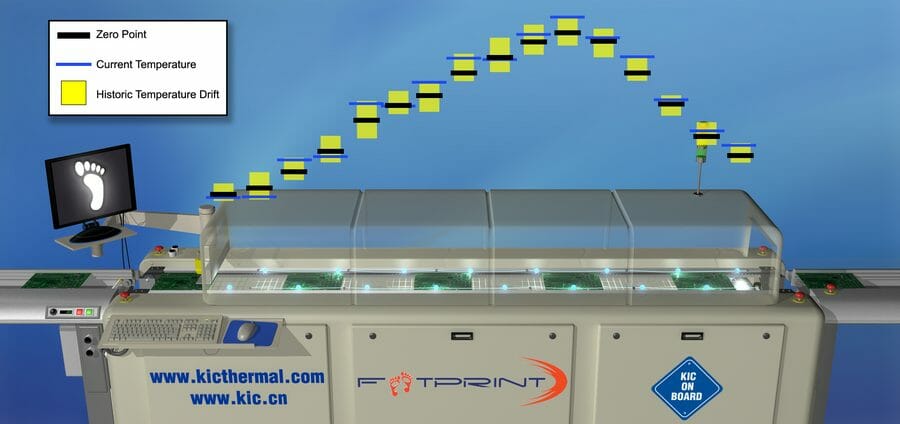

Footprint

An alternative to frequent profiling, the Footprint system monitors the oven temperature variations along the conveyor. The key decision is to determine allowable versus excessive drift and the Footprint can make that decision for you by automatically measuring the acceptable drift, and only alert the user when the conditions reach danger level.

KIC Vision²

KIC Vision² periodically and automatically profiles reflow and curing ovens. Reduce production cost, downtime, and human error with this uncomplicated, low cost system.